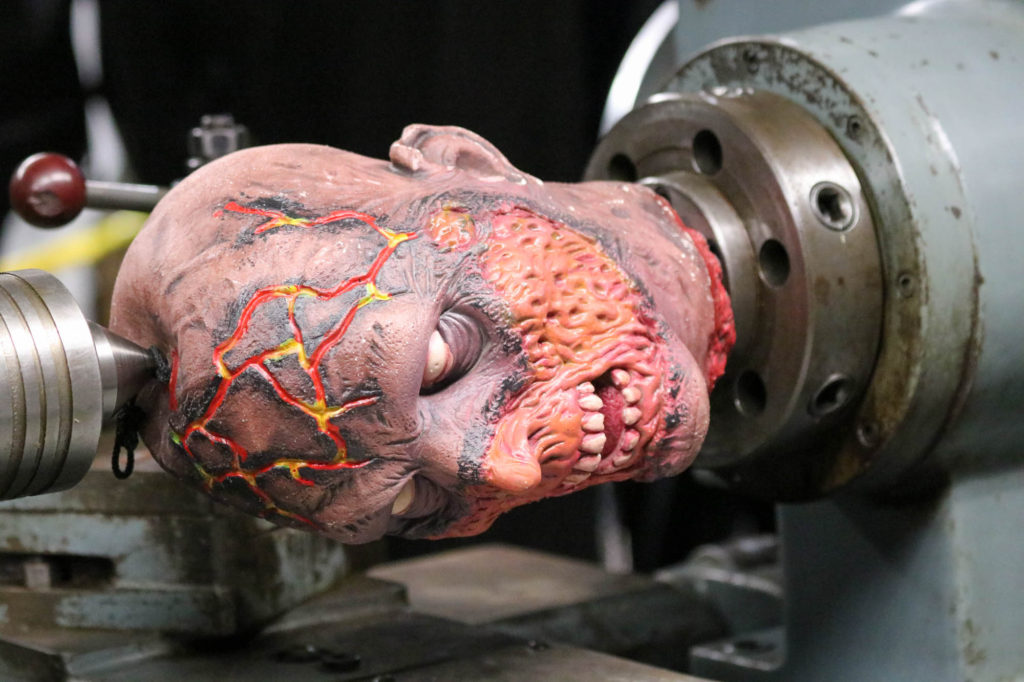

A workshop filled with severed body parts, machines covered in cobwebs and a bucket of blood hardly sounds inviting—unless it’s Halloween.

The Society of Manufacturing Engineers transformed its workshop into a three-day haunted maze they dubbed “Horror Shop” to fundraise for their club, as explained by SME Adviser Bryce Garter.

“The shop at night is kind of creepy,” Garter said. “We were brainstorming a fundraising opportunity, and it being Halloween season, the group kind of elected to convert the shop.”

Using machines for terrifying demonstrations and to create a pathway through the shop, materials to blackout the windows and well placed decorations, the SME used their skills and elbow grease to give Pierce some real scares.

Garter also explained that while the scares were real, so were the safety precautions necessary when dealing with a room full of dangerous machinery.

“Shop safety is number one,” Garter said. “We issue safety glasses and we will observe the rules of shop safety. Only trained personnel will be operating the machines and power for many of the machines will be cut at the main breaker so that the machine can’t be activated.”

Welding Club representative Travis Gonzales took time from his pursuit of a Welding Certificate to partake in the Horror Shop and encouraged others to experience it as well.

“It was extremely scary, blood everywhere, I would highly recommend it,” Gonzales said. “If you want to be scared out of your mind, check it out.”

While he enjoyed the maze overall, there were a few things about the maze that stuck out to Gonzales.

“Rotating heads on a lathe machine, a guy doing some grinding that was pretty cool.” Gonzales said.

Even though he went into the shop with knowledge and intent of being scared, there were still some aspects that caught him off guard.

“I’ve actually taken a class in that room,” Gonzales said. “All of this stuff that they did and the whole experience was really good and the way they transformed the [room] was very impressive.

Club President and Genetic Engineering major Jeffrey Lerner explained that when the club is not trying to scare the student population, they are busy at work using their talents to bring ideas to life.

“We’re making a case for Raspberry Pi,” Lerner said. “We need to make several prototypes as well as back up money and are hoping to raise $600-$900.”

Despite the name, the case is not for a delicious dessert, the Raspberry Pi is a computer chip, and as such the case will provide more than just protection.

“It will cool down the motherboard so that it can be overclocked a higher project processing ability,” Lerner said. “We are also going to make it waterproof. These capabilities will allow it to be in robots in turn, expanding their abilities.”

While this is their first hosting the event, the SME club hopes it to be a continuing event that they can do every year and start building traction.